GMP SRL

Phone +39 0438 82354 – 82547

email info@gmp.it

Via Sernaglia, 74

31053 Pieve di Soligo (TV) – Italy

TECHNOLOGY

ADVANCED

FEATURES

FOR UNIQUE

IRONERS

CUSTOMIZE AN

OUTSTANDING IRONER

THE SPECIFIC MARKET KNOWLEDGE AND THE CONTINUOUS RESEARCH HAVE ENABLED GMP TO DEVELOP UNIQUE TECHNOLOGICAL SOLUTIONS, ABLE TO RAISE THE QUALITY OF THE PROFESSIONAL IRONING MACHINE, FURTHER EXTENDING THE IRONER LIFESPAN, KEEPING PERFORMANCE AT EXCELLENT LEVEL AND SIMPLIFYING DAILY OPERATION.

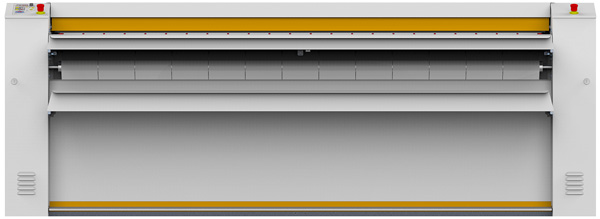

GEMINI

TWIN TEMPERATURE

CONTROL

STANDARD

E LINE, G LINE, GMP.30 MODELS

GEMINI TWIN TEMPERATURE CONTROL HAS BEEN SPECIFICALLY DEVELOPED BY GMP TO ADDRESS ONE OF THE MOST COMMON PROBLEMATIC ON FLATWORK IRONERS – LOCALIZED OVERHEATING (TYPICALLY ROLLER COVER GETTING BROWN ON ONE SIDE), WHICH HAPPENS WHEN LINEN INTRODUCTION IS MOSTLY DONE USING ONLY A PART OF THE USEFUL FEEDING SURFACE.

It is characterized by the presence of 2 temperature sensors monitoring the whole ironing surface and automatically cutting off the heating when unbalances or limit temperatures are detected.

- Avoids fluctuations

- Extends roller cover’s lifespan

- Protects textiles: no scorching

- No waste of energy

HARD CHROMED

STEEL CHEST

STANDARD

E LINE, GMP.25 AND GMP.30 MODELS

WHY HAVE GMP EXPERTS CHOSEN A STEEL CHEST?

BECAUSE STEEL REPRESENTS THE MOST RELIABLE, EFFICIENT AND LONGER LASTING DESIGN FOR A PROFESSIONAL IRONING MACHINE:

- Steel heats up quickly and keeps a constant temperature during ironing. When feeding moist linen temperature is subtracted from the chest surface: steel conserves the heat better than other materials.

- GMP hard chromed chest has an excellent protection against accidental scratching. Thanks to a specific hard chrome protection treatment, steel becomes extremely resistant to friction, which is the most critical factor in ironing.

- Steel can be cleaned from residuals building up on the ironing surface (detergents, starch, limescale, melt synthetic fibres) without risking to damage the hard chrome treatment.

GMP hard chromed chest is guaranteed 3 years against corrosion.

TENAX

ROLLER PADDING:

LASTING STRENGTH

AVAILABLE

E LINE, GMP.25 AND GMP.30 MODELS

TENAX IS A STAINLESS STEEL PADDING THAT REPLACES THE STANDARD ROLLER PADDING MADE OF STEELWOOL.

PURPOSELY DESIGNED BY GMP FOR ITS IRONERS, TENAX LASTS FOR THE ENTIRE LIFE OF THE IRONER AND OPPOSITE TO THE STEELWOOL DOES NOT REQUIRE ANY MAINTENANCE.

- Entirely realized in 100% stainless steel, TENAX is not subject to deformations: its strong structure remains unaltered in time, guaranteeing identical productivity and perfect contact surface along the whole ironer life.

- TENAX definitely eliminates concerns about roller shrinking, wrinkles, insufficient drying and service cost.

- It grants the maximum efficiency of the steam extraction: thanks to its perforated structure, it allows easy and quick removal of humidity from the ironing surface.

- Medium lifespan of the Meta Aramid cover felt: 4000+ hours.

PATENTED

ROLL REMOVING

SYSTEM:

FAST AND EASY

RECONDITIONING

STANDARD

E LINE

IF YOU OPTED FOR STEELWOOL PADDING, FULLY RECONDITIONING YOUR IRONER IN LESS THAN AN HOUR AND RENOVATING THE ORIGINAL IRONING FINISH IS NOW POSSIBLE, THANKS TO THE PATENTED ”ROLL REMOVING SYSTEM”.

Original GMP spare roll is assembled in the factory by automatic and specifically designed tool machinery, according to the strictest quality standards, and will ensure perfect ironing results.

HARD CHROMED

STEEL CYLINDER

AVAILABLE

G LINE

OPTING FOR A CHROMED CYLINDER IS ALMOST A MUST IN A MODERN WORLD: LINEN DESTINED TO COME IN CONTACT WITH FOOD OR WITH HUMAN SKIN SHOULD NOT BE CONTAMINATED BY OXIDATION PRODUCTS THAT INEVITABLY FORM ON THE SURFACE OF A POLISHED CYLINDER.

- Maximum hygiene: laboratory tests have demonstrated that chromed surfaces are ideal to grant the maximum hygiene, and new researches proved they grant an even better resistance to bacterial growth than stainless steel.

- 3 years warranty: hard chrome coating is guaranteed 3 years against corrosion.

- Reduced ordinary maintenance: no waxing required.

- Constant output: belts maintain their transpiration capacity, while waxing would make them impermeable.

- Improved ironing quality: smoother surface granted by a chromed surface.

PATENTED

VENTURI BURNERS

STANDARD

G LINE

GAS HEATED MODELS USE A PARTICULARLY EFFICIENT BURNER, WHICH HAS BEEN ENTIRELY DEVELOPED AND PATENTED BY GMP FOR THE SPECIFIC USE ON A FLATWORK IRONER.

Thanks to employing the Venturi effect, the burner automatically creates the ideal air/gas mixture that is suctioned and distributed homogeneously along its whole length to obtain a perfectly blue and regular flame, guaranteeing an ideal heat distribution across the whole cylinder.

The burner is realized in titanium-steel and is laser perforated to achieve the maximum accuracy of the flame distribution pattern.

Compared to the traditional atmospheric burners with gas jets, GMP solution:

- Guarantees better performance

- Avoids gas waste.

Moreover it is particularly eco-friendly, with its ppm emission close to zero.

KNURLED

ROLLERS

STANDARD

G LINE

IRONING BELTS DRAFT ROLLERS ARE GENERALLY COVERED WITH A RUBBER OR SILICONE PADDING AIMED TO GUARANTEE THE GRIP NECESSARY FOR BELTS ROTATION. THE RUBBER/SILICONE PADDING CRYSTALLIZES WITH HIGH TEMPERATURES AND COMES OFF WITH THE TIME, LEADING TO IRONER STOP AND TO POSSIBLE BELTS DAMAGES.

GMP has opted for installing padding-free rollers: the knurling process we realize on their metal surface replaces the rubber function, granting the grip necessary for a homogeneous belts traction.

GMP exclusive solution eliminates ironer downtime due to sudden rubber peeling and with it one of the most frequent maintenance operations on a drying ironer.

FSS: FLOATING SUPPORT

SYSTEM FOR HEAVY

CYLINDERS

STANDARD

G.50 MODELS

BECAUSE OF THE 500 MM ROLL DIAMETER, CYLINDERS INSTALLED ON G.50 PROFESSIONAL IRONING MACHINE HAVE AN IMPORTANT WEIGHT THAT NEEDS TO BE WELL DISTRIBUTED TO ENSURE A SMOOTH ROTATION, AVOIDING PREMATURE FAILING OF ITS SUPPORTS.

Differently from bars, GMP cylinder support system does not bend. It is designed to float, actively keeping the cylinder in balance and compensating eventual different belts elongations associated with belts use.

8 cylinder support wheels instead of the usual 4 distribute the weight over twice the rotation surface with a consequent improvement of the single components lifespan.

The absence of bars makes maintenance interventions faster and easier.