GMP SRL

Phone +39 0438 82354 – 82547

email info@gmp.it

Via Sernaglia, 74

31053 Pieve di Soligo (TV) – Italy

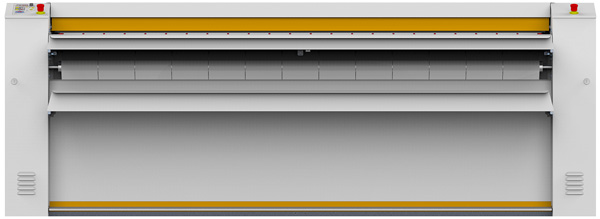

Model

26.50

26.50

26.50

26.50

UNMATCHED DESIGN FOR UNRIVALED, NON-STOP OUTPUT

Description

G.50 has been designed to ensure massive non-stop output, whilst guaranteeing at the same time the high-quality ironing finish characterizing GMP drying ironers.

Strongly built with cutting-edge features like SKS System and FSS System, G.50 represent the ideal choice for the needs of the 4-5 stars hotels and of the small industrial laundries.

SKS System: Special Steam Suction Hood.

A new and specially designed steam extraction technology that offers relevant benefits in comparison to the conventional system:

– Extra-wide steam extraction surface: water will evaporate very quickly from the linen and the belts, allowing working at higher ironing speed.

– Shorter drying times.

– No heat dispersion: because of its special design, the hood will extract only the humidity (steam) without affecting the temperature of the cylinder, eliminating heat dispersions and thus saving on energy costs.

– Extremely silent.

– Easy replacement of the pressure roller ribbons.

FSS: Floating Support System for the cylinder

FSS allows easy and quick replacement of the cylinder support wheels, one of the most common maintenance operations on a drying ironer. It additionally enormously increases system reliability thanks to the homogeneous weight distribution granted by the special design.

8 cylinder support rollers instead of the standard 4 additionally reduce wear and tear on the single components, extending their lifespan.

- Hotels up to 150 rooms

- Restaurants

- Catering activities

- Sport clubs

- Communities

- Schools

- Nursing and care homes

- Shipboard laundries

- Oil rigs

- Small industrial laundries

- Dry cleaning shops

Technical data

| Cylinder Dimensions | 2580 x Ø500 mm |

| Available Heating Sources | Electric, Gas, Steam |

| Hourly Production | E: 95 kg/h - G: 110 kg/h - S: 115 kg/h (r.h. 50%) |

| Heating Power | 57 kW |

| Gas Consumption | G20: 7 m³/h - LPG: 5 kg/h |

| Steam Consumption | 70 kg/h |

| Standard Supply Voltage | 400/3N |

| Ironing Speed | 1,6 ÷ 8 m/min |

| Ironer Dimensions | 3280 x 750 x 1290 mm |

| Net Weight | 1320 kg |