Hotel industry is continuing its development toward high levels of hospitality and a comfortable king-size bed is no more an option: on the contrary, it is becoming the new standard.

Changes in bedsheets dimensions naturally reflect on equipment needed to process them to ensure the excellent ironing quality a guest expects to find when walking into his hotel room.

First impression is crucial indeed and well ironed bedsheets immediately give a reference about the hygienic standards followed by the place where we have decided to spend our holidays or to get a good sleep after an exhausting business day.

However, ironing a king-size bedsheet without folding has been just a wish until now for several businesses: the investment for the equipment and the electrical/thermal power required for a 3.2 m industrial flatwork ironer by 500 mm roll diameter would put it on the wish list, but out of reach.

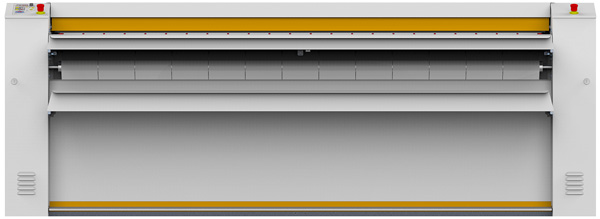

GMP has specifically designed G32.35 to meet the needs of the activities looking for a balance between ironing quality, productivity and budget.

The advantages of choosing G32.35 industrial flatwork ironer:

- Its 3.2 m wide ironing surface allows to process large bed sheets without folding, ensuring a perfect ironing quality.

- Process times are reduced compared to ironing folded sheets, with benefits on labour costs, while productivity increases dramatically.

- The compact 325 mm roll diameter allows working with reduced energy requirements compared to the 500 mm roll model.

- G32.35 is an affordable investment.