GMP SRL

Phone +39 0438 82354 – 82547

email info@gmp.it

Via Sernaglia, 74

31053 Pieve di Soligo (TV) – Italy

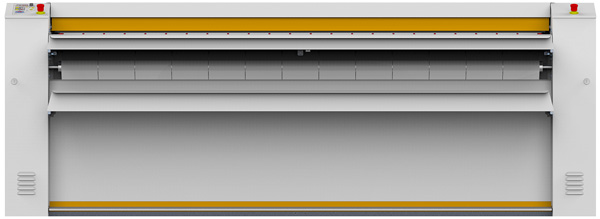

Model

15.35

15.35

15.35

15.35

UNMATCHED FINISH & SUPERIOR PERFORMANCES

Description

G.35 drying ironers are worldwide recognized for the unmatched ironing finish, obtained thanks to a specifically studied pressure roller that allows treating even the most complex and delicate fabrics including silk, organza, satin, and embroidered fabrics.

Being an ironer specialist manufacturer allows GMP to concentrate its complete R&D effort and production structure to process internally the components, which represent the heart of the ironing process.

Results are clearly visible and appreciated: G.35 commercial flatwork ironer is tremendously strong and reliable, and is manufactured using high-quality oversized parts. Its superior quality made G.35 successfully affirm even on the most exigent European markets, indeed.

Following the same design philosophy applied to ironers for decades, GMP has designed for G.35 commercial flatwork ironer low maintenance solutions, which result in concrete benefits such as reduced ownership and maintenance costs over the years.

G.35 has proven giving excellent ironing results on catering round-shaped table clothes, and especially on the bright polycotton fabrics, or the high-quality cotton or linen. In fact, ironing with belts technology represents a big advantage when processing round or oval catering table cloths because it avoids any fibre distortion.

An efficient temperature control, with reactive sensors and an excellent management of the power installed gives performances above the average and at same time avoids any energy waste.

- Hotels up to 70 rooms

- Restaurants

- Catering activities

- Sport clubs

- Communities

- Schools

- Nursing and care homes

- Shipboard laundries

- Oil rigs

- Small industrial laundries

- Dry cleaning shops

Technical data

| Cylinder Dimensions | 1480 x Ø325 mm |

| Available Heating Sources | Electric, Steam |

| Hourly Production | 43 kg (r.h. 50%) |

| Heating Power | 20,7 kW |

| Steam Consumption | 19 kg/h |

| Standard Supply Voltage | E: 400/3N - S: 230/1N |

| Ironing Speed | 1,6 ÷ 5 m/min |

| Ironer Dimensions | 2010 x 550 x 1100 mm |

| Net Weight | 450 kg |